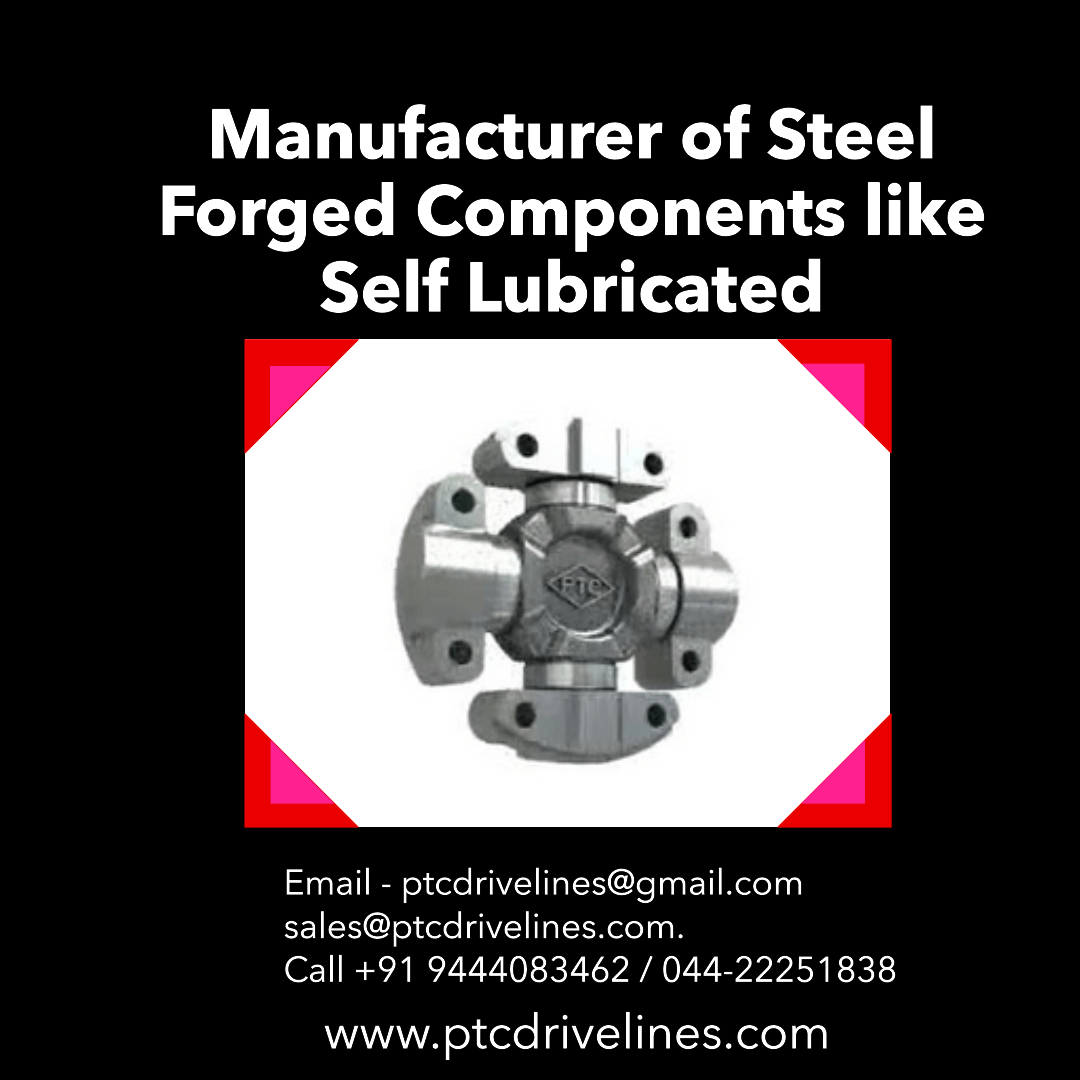

Manufacturer of Steel Forged Components like Self Lubricated

PTC Drivelines is a a leading Manufacturer of Steel Forged Components like Self Lubricated Universal Joints & Propeller Shafts for use in Automobiles, Earthmoving Equipments, & Diesel Locomotives

Steel forged components are widely used in various industries due to their strength, durability, and reliability. They are commonly used in automotive, aerospace, construction, and oil and gas sectors.To know more visit our website www.ptcdrivelines.com .

Manufacturer of Steel

As a reputable manufacturer of steel, we pride ourselves on delivering high-quality products that meet the diverse needs of our customers. With years of industry experience and expertise, we have established ourselves as a trusted provider of top-grade steel materials. Our commitment to excellence drives us to continuously innovate and improve our manufacturing processes, ensuring that our customers receive steel products of the highest standards.

Steel Forged Components

Steel-forged components are engineered to withstand demanding applications and deliver exceptional performance. Through our precise forging techniques, we create components that exhibit superior strength, durability, and reliability. Whether you require gears, shafts, or other critical parts, our steel-forged components are designed to meet your exact specifications and deliver optimal results in various industries.

Best Manufacturer of Steel Forged Components like Self Lubricated

PTC manufactures “C”, DIN and SAE type universal Joints for Off-Highway (Earthmoving Equipements in Mining Industries), Highway (Commercial Vehicles), Locomotive and Industrial Equipements.

Self-Lubricated Components

Experience the advantages of self-lubricated components that reduce friction, minimize wear, and enhance overall efficiency. Self-lubricated components are engineered with advanced materials and coatings that provide continuous lubrication, eliminating the need for external lubricants and ensuring smooth operation. By reducing maintenance requirements and extending component life, these self-lubricated solutions offer cost-effective benefits and improved performance.

High-Quality Forgings

Our commitment to delivering high-quality forgings sets us apart in the industry. We utilize state-of-the-art manufacturing processes and stringent quality control measures to ensure that every forging meets the highest standards of excellence. Our team of skilled craftsmen and engineers work meticulously to produce forgings that exhibit exceptional strength, precision, and reliability, making them ideal for critical applications where quality is paramount.

Industrial Steel Parts

From heavy machinery to complex industrial systems, our industrial steel parts are designed to withstand the toughest conditions and deliver optimal performance. We offer a comprehensive range of steel parts, including components for power generation, manufacturing, construction, and more. With our focus on precision engineering and durability, our industrial steel parts provide the reliability and longevity required in demanding industrial environments.

PTC manufactures “C”, DIN, SAE and Serration type Propeller Shafts for Off-Highway (Earthmoving Equipements in Mining Industries), Highway (Commercial Vehicles), Locomotive and Industrial Equipements.

Durable Forged Components

Our durable forged components are crafted to endure extreme conditions and heavy loads without compromising performance. Through our advanced forging techniques and meticulous attention to detail, we create components that exhibit exceptional durability, resistance to wear, and structural integrity. Whether you need components for automotive, aerospace, or other industries, our durable forged components are built to last.

Custom Steel Forgings

At our facility, we specialize in creating custom steel forgings tailored to your unique requirements. Our team of experts works closely with you to understand your specifications and design custom forgings that meet your exact needs. With our state-of-the-art equipment and expertise, we can produce highly complex and precise forgings, ensuring that your custom steel components perform flawlessly in your specific application.

Performance Steel Parts

Experience enhanced performance with our high-quality steel parts engineered for optimal functionality. Our performance steel parts are designed to deliver superior strength, reliability, and efficiency, making them suitable for a wide range of applications. Whether you need components for automotive, aerospace, construction, mining, or industrial machinery, our performance steel parts are crafted to maximize performance and exceed your expectations.

Reliable Steel Components

When it comes to reliability, our steel components are second to none. We understand the importance of dependable components in critical applications, which is why we prioritize quality, precision, and adherence to industry standards. Our reliable steel components undergo rigorous testing and quality assurance processes to ensure they meet the highest performance and reliability standards, providing peace of mind to our customers.

KOMATSU SPIDER42C-20-12621/42C-20-12620

KOMATSU SPIDER428-20-12620 / 561-20-12102

KOMATSU SPIDER 281-20-12201 / 562-20-11100

KOMATSU SPIDER561-20-71100

KOMATSU DRIVE SHAFT561-20-72002 / 561-20-72003

KOMATSU DRIVE SHAFT 561-20-71000

KOMATSU DRIVE SHAFT 569-20-72000

KOMATSU DRIVESHAFT569-20-71000

KOMATSU DRIVESHAFT 562-20-32801

KOMATSU WHEEL BOLT 569-22-72850/ 569-22-72860

CAT SPIDER106-0933

CAT SPIDER 8X0432 / 363-1923

CAT SPIDER 9V7710 / 173-0888

CATDRIVESHAFT142-2886 /172-5232 / 2G4080

CATDRIVESHAFT 8X0498 / 8X0473

Cost-Effective Forgings

Our cost-effective forgings offer exceptional value without compromising on quality or performance. Through efficient manufacturing processes and optimization techniques, we can provide competitively priced forgings that meet the stringent requirements of various industries. With our cost-effective forgings, you can achieve the desired results within your budgetary constraints, making them an ideal choice for both small-scale and large-scale projects.

PTC manufactures High Tensile fasteners upto size 40mm in both mm & inch bolts.

Long-Lasting Steel Parts

Our long-lasting steel parts are engineered to withstand the test of time, ensuring optimal performance and reliability throughout their lifespan. By utilizing high-quality materials and employing advanced manufacturing techniques, we create steel parts that are resistant to wear, corrosion, and fatigue. Whether you need components for heavy machinery, infrastructure, or other applications, our long-lasting steel parts are designed to deliver enduring performance.

Industrial Forging Company

As a leading industrial forging company, we possess the expertise, infrastructure, and capabilities to cater to the diverse needs of industries worldwide. With our state-of-the-art facilities and skilled workforce, we offer comprehensive forging solutions, from design and prototyping to production and finishing. We are committed to providing our clients with top-quality forgings that meet their specific requirements, backed by exceptional customer service and on-time delivery.

Self-Lubrication Benefits

Discover the numerous benefits of self-lubrication in your applications. Self-lubricated components offer advantages such as reduced friction, improved wear resistance, extended component life, and increased operational efficiency. By eliminating the need for external lubricants and reducing maintenance requirements, our self-lubrication solutions help you save time, costs, and resources while enhancing the overall performance of your systems.

Steel Forging Process

Our steel forging process combines traditional craftsmanship with modern technology to create forged components of the highest quality. From selecting the finest steel materials to employing precision forging techniques, our process ensures that every component exhibits excellent strength, integrity, and dimensional accuracy. With our commitment to excellence in every stage of the forging process, we guarantee superior results that meet your specific requirements.

Customization Options

Experience the flexibility of customization with our wide range of options for steel components. We understand that each application has unique demands, which is why we offer extensive customization options to tailor our products to your exact specifications. From dimensions and materials to surface finishes and special features, our customization options allow you to optimize the performance and functionality of our steel components for your specific needs.

High-Temperature Forgings

Our high-temperature forgings are engineered to withstand extreme heat and maintain their structural integrity under challenging conditions. Designed for applications requiring resistance to thermal stresses, our high-temperature forgings exhibit exceptional strength, dimensional stability, and heat resistance. Whether you need components for aerospace, power generation, or other high-temperature environments, our forgings are capable of meeting your stringent requirements.

Environmental Friendly

At our company PTC Drivelines, we are committed to environmentally friendly practices throughout our manufacturing processes. We adhere to sustainable manufacturing principles, prioritize recycling and waste reduction, and utilize energy-efficient technologies to minimize our carbon footprint. By choosing our environmentally friendly steel components, you not only receive high-quality products but also contribute to a greener and more sustainable future.

Operational Efficiency

Boost your operational efficiency with our precision-engineered steel components. Designed to optimize performance, reduce downtime, and enhance productivity, our components are crafted to deliver seamless integration into your systems. With our focus on quality, reliability, and adherence to industry standards, our steel components help you achieve operational excellence and maximize the efficiency of your processes.

Q1:What are self-lubricated steel forged components?

A1: Self-lubricated steel forged components are specialized components that incorporate built-in lubrication properties. These components are designed to reduce friction and wear by providing continuous lubrication, eliminating the need for external lubricants.

Q2: What industries use self-lubricated steel forged components?

A2: Self-lubricated steel forged components find applications across various industries, including automotive, aerospace, industrial machinery, power generation, and more. They are commonly used in high-load, high-performance systems where reduced friction and improved durability are essential.

Q3: What are the advantages of self-lubricated steel forged components?

A3: The advantages of self-lubricated steel forged components include reduced friction and wear, improved performance and efficiency, extended component life, minimized maintenance requirements, enhanced reliability, and cost savings associated with reduced lubrication needs.

Q4: How can I ensure the quality of self-lubricated steel forged components?

A4: To ensure the quality of self-lubricated steel forged components, it is crucial to source them from reputable manufacturers with a track record of delivering high-quality products. Look for manufacturers that follow stringent quality control processes, adhere to industry standards, and have a reputation for producing reliable and durable components.

Q5: Are self-lubricated steel forged components cost-effective?

A5: Yes, self-lubricated steel forged components are cost-effective in the long run. While they may have a slightly higher upfront cost compared to standard components, the elimination of external lubricants, reduced maintenance requirements, and extended component life result in overall cost savings and improved operational efficiency.

Q6: Can self-lubricated steel forged components be customized?

A6: Yes, self-lubricated steel forged components can be customized to meet specific requirements. Reputable manufacturers offer customization options such as dimensions, materials, lubricant types, and surface finishes to ensure the components perfectly fit the intended application.

Q7: Are self-lubricated steel forged components suitable for high-temperature applications?

A7: Yes, self-lubricated steel forged components can be engineered to withstand high-temperature environments. By utilizing appropriate lubrication materials and designs, these components can maintain their lubrication properties and structural integrity even at elevated temperatures.

Q8: How do self-lubricated steel forged components improve operational efficiency?

A8: Self-lubricated steel forged components improve operational efficiency by reducing friction, minimizing wear, and optimizing performance. The built-in lubrication eliminates the need for external lubricants, reducing maintenance intervals, minimizing downtime, and improving overall system reliability and productivity.

Q9: Are self-lubricated steel forged components environmentally friendly?

A9: Yes, self-lubricated steel forged components are environmentally friendly. The reduced need for external lubricants means fewer lubricants are consumed, resulting in lower environmental impact. Additionally, the extended component life and improved efficiency contribute to resource conservation and sustainability.

Q10: What is the production process for self-lubricated steel forged components?

A10: The production process for self-lubricated steel forged components involves precise forging techniques combined with incorporating lubrication properties. It typically includes steps such as material selection, forging, heat treatment, machining, and incorporating the self-lubrication mechanism. Reputable manufacturers follow stringent quality control measures and employ advanced technologies to ensure the production of high-quality self-lubricated steel forged components.

Leave a Reply